Central Vacuum Cleaning System

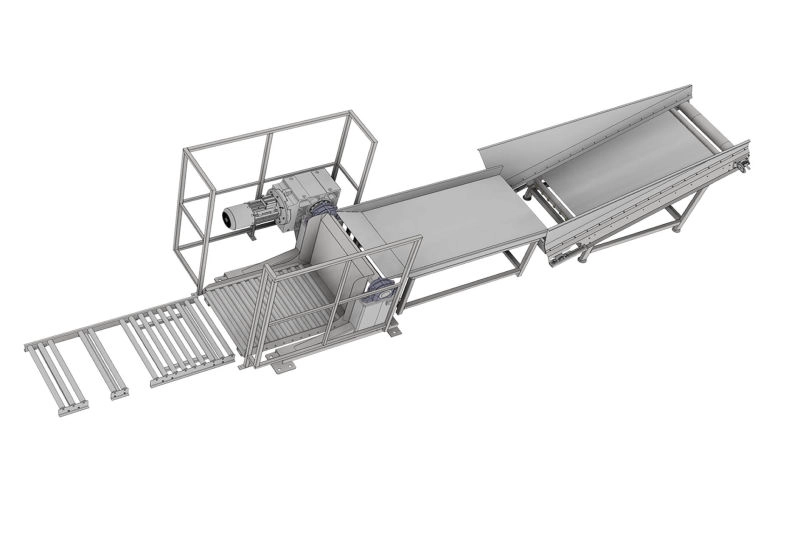

Central Vacuum Cleaning System Tipper

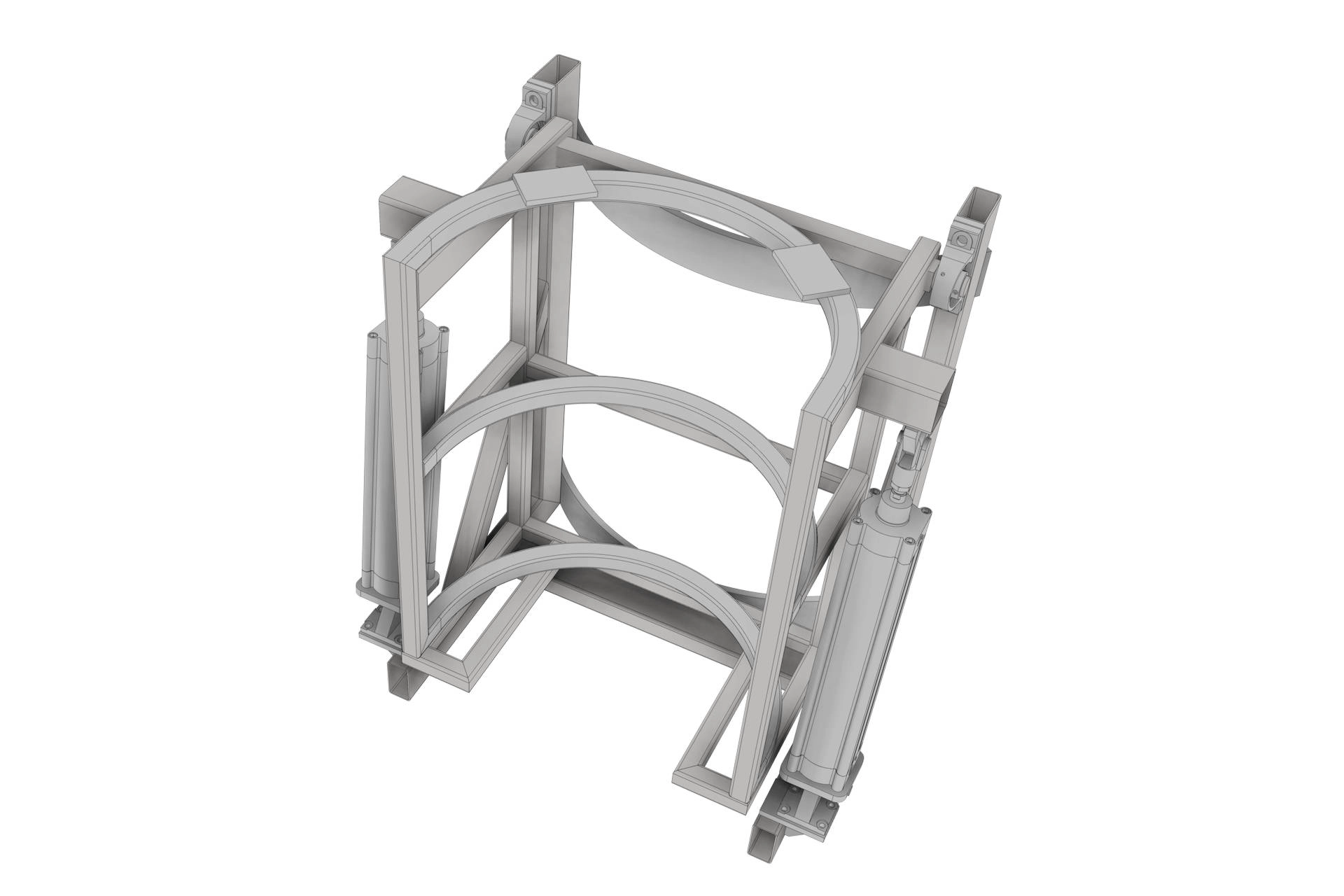

Tipper

Barrel Tipper

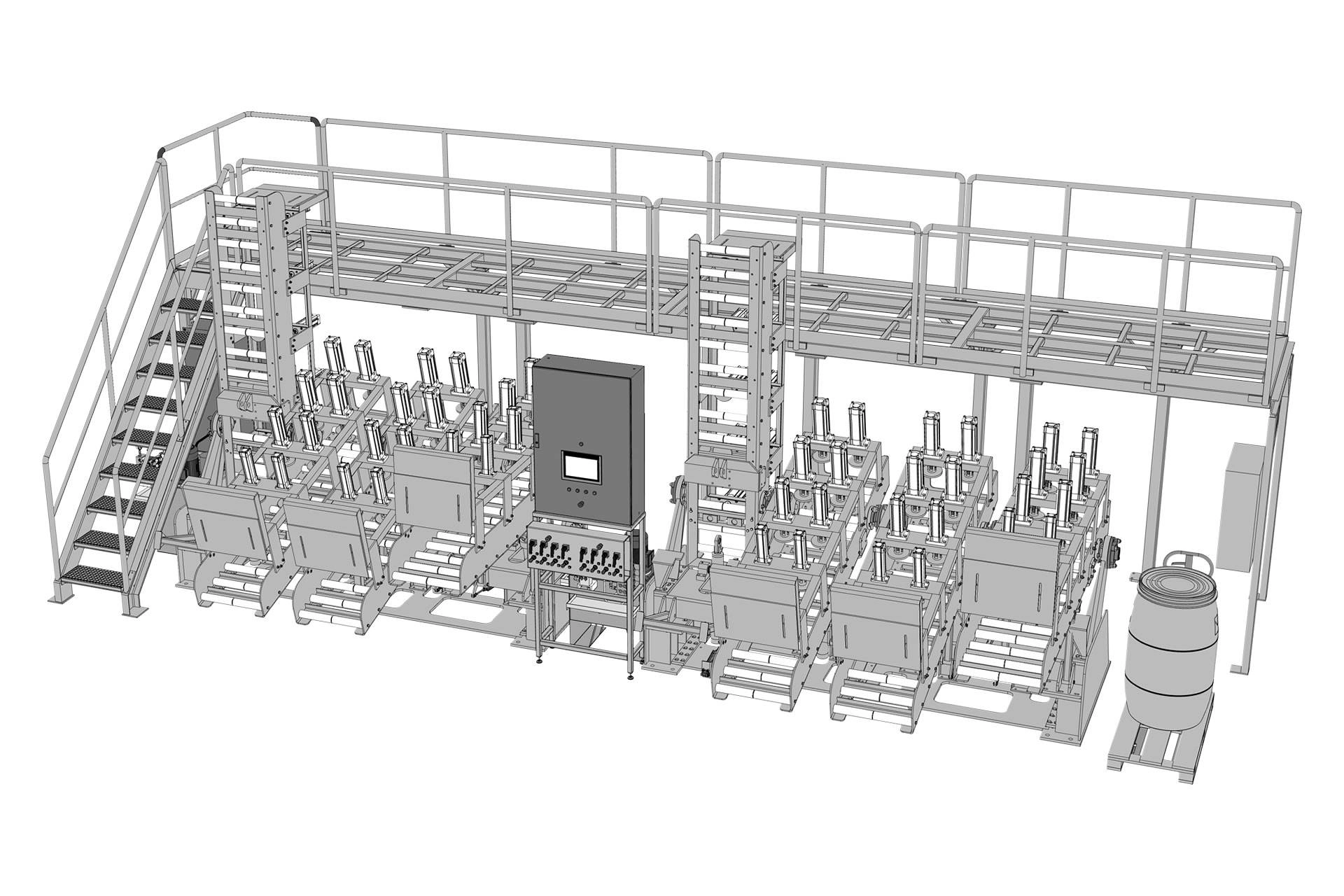

Casting Racks

Casting RacksOPTIMAL Mechatronics & International Engineering Corporation offers engineering and automation consulting services and expertise for industrial manufacturing companies in need of technical recommendation for short-term and long-term courses of action to handle a given initiative.

The ultimate purpose is to produce the most efficient industrial manufacturing solutions for businesses to reduce the time, energy, effort, yield loss and so the money to be spent to the minimum while improving practicality, functionality and technicality of the machinery and equipment to be used to the maximum when performing a specific task.

In order to do a comprehensive feasibility study, OPTIMAL Mechatronics professionals visit the customer at their own facility to investigate and identify the need or in some situations, a problem. The business may need a single machine and a piece of equipment or a set of industrial machinery and equipment to run a process. Or probably, a machine might have broken down. In some circumstances, the business may want to have a whole line such as a production line, packaging and labelling line, packing line, waste chemical cleansing line, conveying line, etc. set up from scratch.

At that point, OPTIMAL steps in to make professional suggestions for selecting the most suitable industrial machinery and equipment to be used; explain how functional,economical,ergonomic and user-friendly the alternatives are; compare their actual capacity of production versus the desired output of production, show the most optimum coordinates of the location of those machinery and equipment at the plant; assist with maintenance and automation; propose alternative solutions for recycling to guide the company follow both an enviro-friendly production strategy and reduce production loss to a minimum; establish and install the utilities infrastructure; make recommendations to adopt the most effective safety precautions, thus conforming to the flow of the process as well as international manufacturing standards.

The essential purpose here is to enable the manufacturer to continue and finalize their processes with minimum error and maximum profitability.

Modern day advancements and innovations in technology, frequently updated government regulations and fierce competition require every business entity to adapt to the latest changes applying the most efficient and optimal methods using the most budget-friendly strategies in the shortest time possible in order to weather the storm and thus survive in the business jungle. That is when OPTIMAL Mechatronics & International Engineering Corporation lends a helping hand as a solution partner.

We visit our customers at their facilities to listen to them and understand their needs perfectly well. We question what their target amount or quantity of output is, how much time and money the business wants to spend for the process, how many workers they are planning to employ for that process or whether they want to follow a totally humanless automated process, if it is a very industry-specific machinery or not, what the delivery deadline of the project is.

Following a mutual discussion of their options, in line with the nature of their needs, problems and the purpose of their investment, we come up with industry-specific mechatronic solutions, high-technology, labour-saving, energy-saving and time-saving remedies that are definitely cost-effective.

At this stage, another significant factor to consider is, of course, to meet the customer’s technical design parameters ensuring that the output will suit the requirements and regulations of international industry standards for manufacturing, fulfil the latest government policies and regulations affecting the future of your industry. When the customer sends OPTIMAL the technical specifications, we create a meticulously prepared 3D design of the machinery, equipment, facility and the line that will suit their need. In this way, we visualize the product. The customer is welcome to make a change on the project before the manufacturing starts as long as it is technically approved by OPTIMAL.

If you need a helping hand, OPTIMAL will be there for you. You name it, we’ll make it!

We are just an e-mail away, not a mile away!

> Dedusting / Dust Collection System

> Central Vacuum Cleaning System

> Oil Bath Suction System

> Complicated Materials Handling System

> Pneumatic Transfer System

> Tobacco Feeding System

> Carbon Steel and Stainless Steel Piping System for Hot Air Exhaust, Cooling Tower,

Fabric Drying Plant, Sewage, Water Transfer and also Ducting System

> Safety Cap System for Cigarette Makers

> Stainless Steel Chimney System

> Silo Unloading Screw Conveyor System

> Big-Bag Weighing System

> Turnkey Grease Plant

> Welding Smoke Suction System

> Turnkey Energy Generation Facility

> Waste Heat Ducting System

> Granule Sorting System

> Margarine Production Line